Your cart is currently empty!

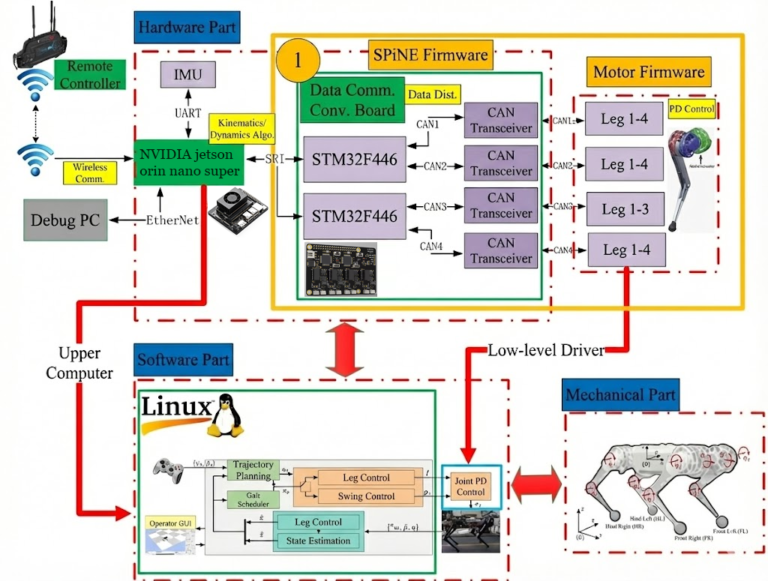

This article aims to systematically analyze the technical architecture and implementation details of the MIT Cheetah robot. The content is compiled from publicly available materials and combined with personal practical understanding, intended to provide reference for relevant technical developers.

MIT Cheetah System Architecture Diagram:

Data Communication Protocol Architecture Diagram:

1. Introduction to mbedOS

Developers who first encounter the MIT Cheetah project may notice that the codebase on GitHub is relatively small, and the compilation method differs from conventional projects. This is primarily because the project uses mbedOS as its underlying development framework.

The hardware modules of MIT Cheetah have relatively small code volumes. For example, the SPIne module primarily focuses on data interaction processing, while underlying hardware drivers and other basic functions are provided by mbedOS.

mbedOS is a complete software solution developed by ARM for IoT applications, and it is an embedded open-source ecosystem targeting ARM Cortex-M series processors. For more information, please visit the mbedOS official website.

The following example demonstrates how to initialize the SPI interface in the SPIne module:

void init_spi(void){

SPISlave *spi = new SPISlave(PA_7, PA_6, PA_5, PA_4);

spi->format(16, 0); // 16bit

spi->frequency(12000000); // 12M

spi->reply(0x0);

cs.fall(&spi_isr);

printf("done\n\r");

}The following is a typical application example of CAN bus communication:

#include "mbed.h"

DigitalOut myled(D8);

CAN can1(PD_0, PD_1,500000);

int main() {

CANMessage msg;

while(1) {

if(can1.read(msg)) {

printf("Message received:id=%d,type=%d,%d\n", msg.id,msg.type,msg.data[0]);

myled = !myled;

}

}

}

2. MIT Cheetah Open Source Resources

The following are open source resource links related to the MIT Cheetah project:

Hardware Related:

▪️ Motor Controller Hardware: https://github.com/bgkatz/3phase_integrated

▪️ SPIne Hardware: https://github.com/bgkatz/SPIne

Software Related:

▪️ Motor Controller Software: https://os.mbed.com/users/benkatz/code/Hobbyking_Cheetah_Compact_DRV8323/

▪️ SPIne Software: https://os.mbed.com/users/benkatz/code/SPIne/

▪️ Linux Control Code (Cheetah Mini): https://github.com/mit-biomimetics/Cheetah-Software

3. MIT Mini Cheetah Robot System

3.1 Simulation Environment Configuration and Usage

After compilation is complete, you need to configure the simulation environment parameters. Navigate to the config directory under the MIT main folder, open the mini-cheetah-defaults.yaml file, set control_mode and cheater_mode to 1, and set use_rc to 0. After configuration, save and exit, as shown in the following figure:

Next, start the robot simulation environment. It is recommended to connect a game controller before starting (optional, for subsequent control). Navigate to the build directory under the MIT main folder (Note: directly entering the sim subdirectory may prevent the simulation from starting, so execute in the build directory), right-click in a blank area and select “Open in Terminal”, then execute the following command:

./sim/sim

After execution, the robot simulation control interface will be displayed, as shown in the following figure:

In the control interface, click “Mini Cheetah” and “Simulator” in sequence, then click the “Start” button to launch the robot simulation interface, as shown in the following figure:

Next, start the robot controller. Navigate to the build/user/MIT_Controller directory under the MIT main folder, right-click in a blank area and select “Open in Terminal”, then execute the following command:

./mit_ctrl m s

Here, mit_ctrl is the compiled executable file, parameter m represents the mini cheetah model, and parameter s represents simulate (simulation mode). After execution, the robot in the simulation should be able to stand up. At this point, switch to the simulation control interface and change the control_mode value to 4. You can observe that the robot in the simulation switches to trot (trotting gait), as shown in the following figure:

At this point, you can control the robot’s movement speed through the game controller’s joystick. Readers can explore different control modes on their own. The following describes the implementation method for backflip operation:

1. Change the control_mode value in the simulation control interface to 3, and the robot will enter a standing state

2. Change the control_mode value to 9, and the robot will perform a backflip action

3. After the backflip is complete, change the control_mode value to 3 again, then change it to 9 to repeat the backflip

Note: If the robot falls during operation, you can click the “Go Home” button in the simulation control interface to restore the robot to its initial position. If it cannot be restored, you need to restart the simulation and controller.

3.2 Real Robot and Simulation Combined Usage

When running the real robot, you need to start both the simulation interface and the controller program:

# Terminal 1: Start simulation interface

./sim/sim

# Terminal 2: Start controller (real robot mode)

./mit_ctrl m r f

Here, parameter r represents robot (real robot mode), and parameter f represents other configuration options.

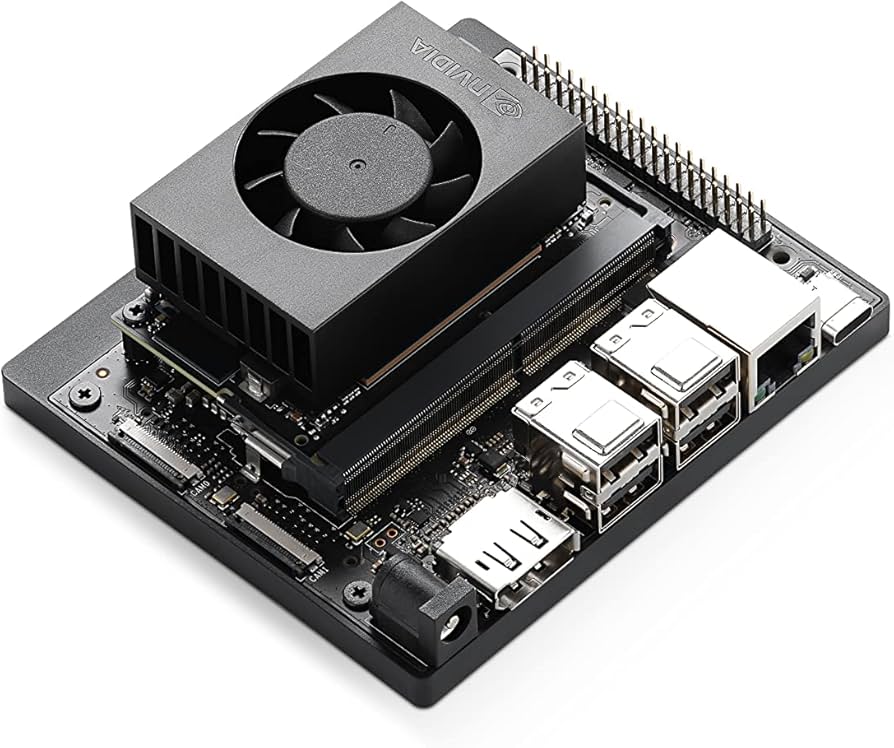

4. Computer Board Selection

The original MIT Mini Cheetah system runs on UP Board, which uses a 4-core Intel Atom x5-Z8350 processor, equipped with 4GB RAM, peak power consumption of approximately 5W, based on x86 architecture.

UP Board has relatively few applications in the Chinese market. More common choices include Raspberry Pi and NVIDIA Jetson Nano. Among them, Raspberry Pi is more oriented towards general embedded applications, while Jetson Nano is more suitable for image processing and AI model deployment.

The solution described in this article uses Jetson Nano as the computing platform, running Ubuntu 22 system, equipped with a 6-core ARM Cortex-A78AE v8.2 64-bit processor (ARM architecture).

It should be noted that for the SPIne board, the GPIO interfaces of UP Board and Jetson Nano are compatible, which provides convenience for platform migration.

4.1 Jetson Nano Software Environment Configuration

The development environment used in this article is Ubuntu 20.04.

4.1.1 Download Cheetah-Software Source Code

git clone https://github.com/fuwei007/NavBot-EG02

4.1.2 Install Third-Party Dependency Libraries

sudo apt-get update

sudo apt -y install cmake gcc build-essential

sudo apt-get -y install openjdk-11-jdk

sudo apt -y install liblcm-dev

sudo apt-get -y install libeigen3-dev

sudo apt-get -y install mesa-common-dev

sudo apt -y install libgl1-mesa-dev

sudo apt -y install libglu1-mesa-dev

sudo apt-get -y install freeglut3-dev

sudo apt-get -y install libblas-dev liblapack-dev

sudo apt-get -y install libopenblas-dev

sudo apt install -y coinor-libipopt-dev gfortran libglib2.0-dev

sudo apt install -y openjdk-8-jdk

4.1.3 Install Qt

Method 1: Source Code Compilation Installation

Download Qt 5.14.2 version: Qt 5.14.2 Download Link

After downloading, navigate to the directory where the file is located, right-click the Qt installation file, select “Properties” → “Permissions”, and check “Allow executing file as program”. Then open a terminal in that directory and execute the following command to start the Qt installation program (Note: the filename in the command should match the actual downloaded filename):

./qt-opensource-linux-x64-5.14.2.run

The installation process is similar to installing programs on Windows, just follow the wizard to complete the installation.

Method 2: Install Using apt Package Manager

sudo apt install -y libqt5 libqt5gamepad5

4.1.4 Install LCM

LCM (Lightweight Communications and Marshalling) is a library for message passing and marshalling.

Download LCM 1.4.0 installation package: LCM v1.4.0 Download Link

After downloading, extract the archive, navigate to the extracted folder, right-click in a blank area and select “Open in Terminal”, then execute the following commands in sequence (it is recommended to execute them one by one):

mkdir build

cd build

cmake ..

make

sudo make install

sudo ldconfig

4.1.5 Install Eigen 3.3.6

Eigen is a C++ template library for linear algebra, matrix and vector operations. Based on practical experience, Eigen 3.3.6 version has good compatibility with the MIT Cheetah project, and other versions may have compatibility issues. It is recommended to use version 3.3.6.

Download Eigen 3.3.6: Eigen 3.3.6 Download Link

After downloading, extract the archive, navigate to the extracted folder, right-click in a blank area and select “Open in Terminal”, then execute the following commands in sequence (it is recommended to execute them one by one):

mkdir build

cd build

cmake ..

make

sudo make install

sudo ldconfig

4.1.6 Modify Source Code Configuration

Navigate to the Cheetah-Software main folder (hereinafter referred to as MIT main folder). The folder structure is shown in the following figure:

The following modifications need to be made:

Step1: Modify Branch Name in CMakeLists.txt

Open the common/CMakeLists.txt file under the MIT main folder, and change master at the position marked in the figure below to main. At the same time, since pulling the googletest library from GitHub is slow in China, it is recommended to switch to the Gitee mirror source.

After modification, save and exit.

step2: Modify Eigen3 and LCM Header File Paths

Modify the header file include paths according to the actual installation path. If Eigen3 and LCM are installed in the /usr/include directory (rather than the default /usr/local/include in the source code), you need to modify the include paths in all related files.

Search and replace the following content:

Original Path:

include_directories("/usr/local/include/lcm/")

include_directories("/usr/local/include/eigen3")Replace with:

include_directories("/usr/include/lcm/")

include_directories("/usr/include/eigen3")List of Files to Modify:

Cheetah-Software-master/common/CMakeLists.txt

Cheetah-Software-master/rc_test/CMakeLists.txt

Cheetah-Software-master/robot/CMakeLists.txt

Cheetah-Software-master/sim/CMakeLists.txt

Cheetah-Software-master/user/MIT_Controller/CMakeLists.txt

step3: Modify Qt Path Configuration

Modify the file Cheetah-Software/scripts/find_qt_path.sh, comment out the default Qt path:

#printf "${HOME}/Qt/${QT_VER}/gcc_64/"Then add your own Qt installation path, as shown in the following figure:

Note: The path after printf should include the bin directory.

step4: Fix Serial Port Header File Missing Issue

Modify the file Cheetah-Software/robot/src/rt/rt_serial.cpp:

▪️ Comment out #include <stropts.h>

▪️ Add #include <sys/ioctl.h> before #include <asm/termios.h>

Then fix the redefinition: vim /usr/include/asm-generic/termios.h Add #ifndef _SYS_IOCTL_H and #endif at the following position:

#ifndef _SYS_IOCTL_H

struct winsize {

unsigned short ws_row;

unsigned short ws_col;

unsigned short ws_xpixel;

unsigned short ws_ypixel;

};

#define NCC 8

struct termio {

unsigned short c_iflag; /* input mode flags */

unsigned short c_oflag; /* output mode flags */

unsigned short c_cflag; /* control mode flags */

unsigned short c_lflag; /* local mode flags */

unsigned char c_line; /* line discipline */

unsigned char c_cc[NCC]; /* control characters */

};

#endif

4.1.7 Compile Program

It is recommended to build inside the mc-build folder at the project root directory :

cd mc-build

rm CMakeCache.txt # Clean up old configuration (if present)

# Configure the project

# -DMINI_CHEETAH_BUILD=TRUE: build the Mini Cheetah version

# -DJCQP_USE_AVX2=OFF: disable x86 AVX2 optimizations, so it suits ARM architectures (e.g., Jetson Nano / NX)

cmake -DMINI_CHEETAH_BUILD=TRUE -DJCQP_USE_AVX2=OFF ..

# Build (adjust the -j parameter according to the number of CPU cores)

make -j4

Notes:

▪️ File deletion related errors that appear when executing ./make_types.sh can be ignored

▪️ The cmake command may get stuck at a certain step (usually related to Google services), which is a network issue and requires patience

▪️ make -j$(nproc) will automatically use all available CPU cores for parallel compilation. If your system doesn’t support this, you can use the make command instead, but compilation speed will be slower

5. SPIne Data Communication Conversion Board

SPIne is a key communication conversion module in the MIT Cheetah system, responsible for data conversion and transmission between the computer board and motor controllers.

Open Source Code Download Address: SPIne Firmware

5.1 Communication Rate Configuration

1. CAN Bus Communication: The communication rate of each CAN bus is configured to 1Mbps. SPIne uses two STM32 microcontrollers because a single CAN bus does not have sufficient bandwidth to support all motor communication requirements. Each STM32 provides two CAN buses, and each CAN bus is responsible for three motors’ communication to achieve a 1000Hz communication frequency. If a single CAN bus is responsible for two legs (six motors), it cannot achieve the required communication frequency.

2. SPI Communication: The SPI communication clock frequency between SPIne and the computer board is 12MHz, with a communication frequency of 1000Hz.

5.2 Communication Data Format

CAN Format: Each frame is 8 bytes.

SPIne → Joint Motor Controller (Command, 8 bytes):

▪️ Position command: 16bit

▪️ Velocity command: 12bit

▪️ Kp (position gain): 12bit

▪️ Kd (velocity gain): 12bit

▪️ Feedforward torque: 12bit

Joint Motor Controller → SPIne (Feedback, 5 bytes):

▪️ Position information: 16bit

▪️ Velocity information: 12bit

▪️ Current (torque): 12bit

PC → SPIne (Command, 132 bytes): Contains 33 data items: position commands, velocity commands, Kp, Kd, and feedforward torque for 6 joints, plus two flags and one checksum.

5.3 Code Architecture

The code structure of the SPIne firmware is shown in the following figure:

Main Module Descriptions:

▪️ leg_message: Responsible for data downlink and uplink encapsulation between UPboard and SPIne, as well as data encapsulation between SPIne and motor controllers

▪️ math_ops: Provides mathematical operation functions

▪️ main: Program main entry function

5.4 Communication Protocol Details

UPboard Computer Board <—-> SPIne Firmware

SPI Communication Protocol:

UPboard Computer Board---->SPIne Firmware

// 60 bytes

// 30 16-bit words

struct spi_data_t

{

float q_abad[2];

float q_hip[2];

float q_knee[2];

float qd_abad[2];

float qd_hip[2];

float qd_knee[2];

int32_t flags[2];

int32_t checksum;

};

UPboard Computer Board<----SPIne Firmware

// 132 bytes

// 66 16-bit words

struct spi_command_t

{

float q_des_abad[2];

float q_des_hip[2];

float q_des_knee[2];

float qd_des_abad[2];

float qd_des_hip[2];

float qd_des_knee[2];

float kp_abad[2];

float kp_hip[2];

float kp_knee[2];

float kd_abad[2];

float kd_hip[2];

float kd_knee[2];

float tau_abad_ff[2];

float tau_hip_ff[2];

float tau_knee_ff[2];

int32_t flags[2];

int32_t checksum;

};

SPIne Firmware <—-> Motor Controller

CAN Communication Protocol:

SPIne Firmware---->Motor Controller

/// CAN Command Packet Structure ///

/// 16 bit position command, between -4*pi and 4*pi

/// 12 bit velocity command, between -30 and + 30 rad/s

/// 12 bit kp, between 0 and 500 N-m/rad

/// 12 bit kd, between 0 and 100 N-m*s/rad

/// 12 bit feed forward torque, between -18 and 18 N-m

/// CAN Packet is 8 8-bit words

/// Formatted as follows. For each quantity, bit 0 is LSB

/// 0: [position[15-8]]

/// 1: [position[7-0]]

/// 2: [velocity[11-4]]

/// 3: [velocity[3-0], kp[11-8]]

/// 4: [kp[7-0]]

/// 5: [kd[11-4]]

/// 6: [kd[3-0], torque[11-8]]

/// 7: [torque[7-0]]

SPIne Firmware<----Motor Controller

/// CAN Reply Packet Structure

/// 16 bit position, between -4*pi and 4*pi

/// 12 bit velocity, between -30 and + 30 rad/s

/// 12 bit current, between -40 and 40;

/// CAN Packet is 5 8-bit words

/// Formatted as follows. For each quantity, bit 0 is LSB

/// 0: [position[15-8]]

/// 1: [position[7-0]]

/// 2: [velocity[11-4]]

/// 3: [velocity[3-0], current[11-8]]

/// 4: [current[7-0]]

5.5 SPIne Firmware SPI Communication Implementation Analysis

5.5.1 Data Buffer Definition

// Receive and transmit byte count

#define RX_LEN 66

#define TX_LEN 66

// SPI data buffer

uint16_t rx_buff[RX_LEN];

uint16_t tx_buff[TX_LEN];

5.5.2 SPIne and UPboard Data Encapsulation Structure

spi_data_t spi_data; // data from spine to up

spi_command_t spi_command; // data from up to spine

// 60 bytes

// 30 16-bit words

struct spi_data_t

{ //position

float q_abad[2];

float q_hip[2];

float q_knee[2];

//velocity

float qd_abad[2];

float qd_hip[2];

float qd_knee[2];

//flags and checksum

int32_t flags[2];

int32_t checksum;

};

// 132 bytes

// 66 16-bit words

struct spi_command_t

{

//position

float q_des_abad[2];

float q_des_hip[2];

float q_des_knee[2];

//velocity

float qd_des_abad[2];

float qd_des_hip[2];

float qd_des_knee[2];

//gain KP

float kp_abad[2];

float kp_hip[2];

float kp_knee[2];

//gain KD

float kd_abad[2];

float kd_hip[2];

float kd_knee[2];

//feedforward torque

float tau_abad_ff[2];

float tau_hip_ff[2];

float tau_knee_ff[2];

//flags and checksum

int32_t flags[2];

int32_t checksum;

};

5.5.3 SPI Interrupt Service Routine

The SPI interrupt service routine is responsible for handling SPI communication data transmission and reception:

void spi_isr(void)

{

GPIOC->ODR |= (1 << 8);

GPIOC->ODR &= ~(1 << 8);

int bytecount = 0;

SPI1->DR = tx_buff[0];

while(cs == 0) {

if(SPI1->SR&0x1) {

rx_buff[bytecount] = SPI1->DR;//data reception

bytecount++;

if(bytecount<TX_LEN) {

SPI1->DR = tx_buff[bytecount];//data transmission

}

}

}

// after reading, save into spi_command

//After reading data, save it in the spi_command structure

// should probably check checksum first!

//data checksum

uint32_t calc_checksum = xor_checksum((uint32_t*)rx_buff,32);

for(int i = 0; i < CMD_LEN; i++)

{

((uint16_t*)(&spi_command))[i] = rx_buff[i];//spi_command data assignment

}

// run control, which fills in tx_buff for the next iteration

//

if(calc_checksum != spi_command.checksum){

spi_data.flags[1] = 0xdead;}

//test_control();

//spi_data.q_abad[0] = 12.0f;

control();//Assign the state information received from the robot motor controller to tx_buff and send it to UPboard via SPI

PackAll();//Write the control data received from UPboard into CAN buffer

WriteAll();//Send CAN buffer data to leg motor controllers via CAN

}

5.5.4 Control Function Implementation

The control() function is responsible for assigning the state information received from the motor controller to tx_buff and sending it to UPboard via SPI:

void control()

{

//Enter motor mode

if(((spi_command.flags[0]&0x1)==1) && (enabled==0)){

enabled = 1;

EnterMotorMode(&a1_can);

can1.write(a1_can);

EnterMotorMode(&a2_can);

can2.write(a2_can);

EnterMotorMode(&k1_can);

can1.write(k1_can);

EnterMotorMode(&k2_can);

can2.write(k2_can);

EnterMotorMode(&h1_can);

can1.write(h1_can);

EnterMotorMode(&h2_can);

can2.write(h2_can);

printf("e\n\r");

return;

}

//Exit motor mode

else if((((spi_command.flags[0]&0x1))==0) && (enabled==1)){

enabled = 0;

ExitMotorMode(&a1_can);

can1.write(a1_can);

ExitMotorMode(&a2_can);

can2.write(a2_can);

ExitMotorMode(&h1_can);

can1.write(h1_can);

ExitMotorMode(&h2_can);

can2.write(h2_can);

ExitMotorMode(&k1_can);

can1.write(k1_can);

ExitMotorMode(&k2_can);

can2.write(k2_can);

printf("x\n\r");

return;

}

//Assign the state information received from the motor controller to spi_data (send to UPboard)

spi_data.q_abad[0] = l1_state.a.p;

spi_data.q_hip[0] = l1_state.h.p;

spi_data.q_knee[0] = l1_state.k.p;

spi_data.qd_abad[0] = l1_state.a.v;

spi_data.qd_hip[0] = l1_state.h.v;

spi_data.qd_knee[0] = l1_state.k.v;

spi_data.q_abad[1] = l2_state.a.p;

spi_data.q_hip[1] = l2_state.h.p;

spi_data.q_knee[1] = l2_state.k.p;

spi_data.qd_abad[1] = l2_state.a.v;

spi_data.qd_hip[1] = l2_state.h.v;

spi_data.qd_knee[1] = l2_state.k.v;

if(estop==0){//Emergency stop

//printf("estopped!!!!\n\r");

memset(&l1_control, 0, sizeof(l1_control));

memset(&l2_control, 0, sizeof(l2_control));

spi_data.flags[0] = 0xdead;

spi_data.flags[1] = 0xdead;

led = 1;

}

else{//Running state, assign the spi_command data received from UPboard to l1_control (send to motor controller)

led = 0;

memset(&l1_control, 0, sizeof(l1_control));

memset(&l2_control, 0, sizeof(l2_control));

l1_control.a.p_des = spi_command.q_des_abad[0];

l1_control.a.v_des = spi_command.qd_des_abad[0];

l1_control.a.kp = spi_command.kp_abad[0];

l1_control.a.kd = spi_command.kd_abad[0];

l1_control.a.t_ff = spi_command.tau_abad_ff[0];

l1_control.h.p_des = spi_command.q_des_hip[0];

l1_control.h.v_des = spi_command.qd_des_hip[0];

l1_control.h.kp = spi_command.kp_hip[0];

l1_control.h.kd = spi_command.kd_hip[0];

l1_control.h.t_ff = spi_command.tau_hip_ff[0];

l1_control.k.p_des = spi_command.q_des_knee[0];

l1_control.k.v_des = spi_command.qd_des_knee[0];

l1_control.k.kp = spi_command.kp_knee[0];

l1_control.k.kd = spi_command.kd_knee[0];

l1_control.k.t_ff = spi_command.tau_knee_ff[0];

l2_control.a.p_des = spi_command.q_des_abad[1];

l2_control.a.v_des = spi_command.qd_des_abad[1];

l2_control.a.kp = spi_command.kp_abad[1];

l2_control.a.kd = spi_command.kd_abad[1];

l2_control.a.t_ff = spi_command.tau_abad_ff[1];

l2_control.h.p_des = spi_command.q_des_hip[1];

l2_control.h.v_des = spi_command.qd_des_hip[1];

l2_control.h.kp = spi_command.kp_hip[1];

l2_control.h.kd = spi_command.kd_hip[1];

l2_control.h.t_ff = spi_command.tau_hip_ff[1];

l2_control.k.p_des = spi_command.q_des_knee[1];

l2_control.k.v_des = spi_command.qd_des_knee[1];

l2_control.k.kp = spi_command.kp_knee[1];

l2_control.k.kd = spi_command.kd_knee[1];

l2_control.k.t_ff = spi_command.tau_knee_ff[1];

//Soft stop program to prevent stopping too abruptly

spi_data.flags[0] = 0;

spi_data.flags[1] = 0;

spi_data.flags[0] |= softstop_joint(l1_state.a, &l1_control.a, A_LIM_P, A_LIM_N);

spi_data.flags[0] |= (softstop_joint(l1_state.h, &l1_control.h, H_LIM_P, H_LIM_N))<<1;

//spi_data.flags[0] |= (softstop_joint(l1_state.k, &l1_control.k, K_LIM_P, K_LIM_N))<<2;

spi_data.flags[1] |= softstop_joint(l2_state.a, &l2_control.a, A_LIM_P, A_LIM_N);

spi_data.flags[1] |= (softstop_joint(l2_state.h, &l2_control.h, H_LIM_P, H_LIM_N))<<1;

//spi_data.flags[1] |= (softstop_joint(l2_state.k, &l2_control.k, K_LIM_P, K_LIM_N))<<2;

}

spi_data.checksum = xor_checksum((uint32_t*)&spi_data,14);

for(int i = 0; i < DATA_LEN; i++){

tx_buff[i] = ((uint16_t*)(&spi_data))[i];}

}

5.5.5 Soft Stop Program Implementation

The soft stop program is used to prevent overly abrupt movements when joint motion exceeds limits:

int softstop_joint(joint_state state, joint_control * control, float limit_p, float limit_n){

if((state.p)>=limit_p){

//control->p_des = limit_p;

control->v_des = 0.0f;

control->kp = 0;

control->kd = KD_SOFTSTOP;

control->t_ff += KP_SOFTSTOP*(limit_p - state.p);

return 1;

}

else if((state.p)<=limit_n){

//control->p_des = limit_n;

control->v_des = 0.0f;

control->kp = 0;

control->kd = KD_SOFTSTOP;

control->t_ff += KP_SOFTSTOP*(limit_n - state.p);

return 1;

}

return 0;

}5.5.6 Data Packing Function

The PackAll() function is responsible for packing the control data received from UPboard into the CAN buffer:

//l1_control encapsulates the data received from UPboard, i.e., encapsulates spi_command

struct leg_control{

joint_control a, h, k;

}

struct joint_control{

float p_des, v_des, kp, kd, t_ff;//position, velocity, KP, KD, torque t_ff

};

void PackAll(){

pack_cmd(&a1_can, l1_control.a); //Left leg 1 ankle motor

pack_cmd(&a2_can, l2_control.a); //Left leg 2 ankle motor

pack_cmd(&h1_can, l1_control.h); //Left leg 1 hip motor

pack_cmd(&h2_can, l2_control.h); //Left leg 2 hip motor

pack_cmd(&k1_can, l1_control.k); //Left leg 1 Knee motor

pack_cmd(&k2_can, l2_control.k); //Right leg 2 Knee motor

}

5.5.7 CAN Data Packing Function

The pack_cmd() function parses the control information sent from UPboard and packs it into the CAN buffer, ready to be sent to the motor controller:

/// CAN Command Packet Structure ///

/// 16 bit position command, between -4*pi and 4*pi

/// 12 bit velocity command, between -30 and + 30 rad/s

/// 12 bit kp, between 0 and 500 N-m/rad

/// 12 bit kd, between 0 and 100 N-m*s/rad

/// 12 bit feed forward torque, between -18 and 18 N-m

/// CAN Packet is 8 8-bit words

/// Formatted as follows. For each quantity, bit 0 is LSB

/// 0: [position[15-8]]

/// 1: [position[7-0]]

/// 2: [velocity[11-4]]

/// 3: [velocity[3-0], kp[11-8]]

/// 4: [kp[7-0]]

/// 5: [kd[11-4]]

/// 6: [kd[3-0], torque[11-8]]

/// 7: [torque[7-0]]

void pack_cmd(CANMessage * msg, joint_control joint){

/// limit data to be within bounds ///

float p_des = fminf(fmaxf(P_MIN, joint.p_des), P_MAX);

float v_des = fminf(fmaxf(V_MIN, joint.v_des), V_MAX);

float kp = fminf(fmaxf(KP_MIN, joint.kp), KP_MAX);

float kd = fminf(fmaxf(KD_MIN, joint.kd), KD_MAX);

float t_ff = fminf(fmaxf(T_MIN, joint.t_ff), T_MAX);

/// convert floats to unsigned ints ///

uint16_t p_int = float_to_uint(p_des, P_MIN, P_MAX, 16);

uint16_t v_int = float_to_uint(v_des, V_MIN, V_MAX, 12);

uint16_t kp_int = float_to_uint(kp, KP_MIN, KP_MAX, 12);

uint16_t kd_int = float_to_uint(kd, KD_MIN, KD_MAX, 12);

uint16_t t_int = float_to_uint(t_ff, T_MIN, T_MAX, 12);

/// pack ints into the can buffer ///

msg->data[0] = p_int>>8;

msg->data[1] = p_int&0xFF;

msg->data[2] = v_int>>4;

msg->data[3] = ((v_int&0xF)<<4)|(kp_int>>8);

msg->data[4] = kp_int&0xFF;

msg->data[5] = kd_int>>4;

msg->data[6] = ((kd_int&0xF)<<4)|(t_int>>8);

msg->data[7] = t_int&0xff;

}

5.5.8 CAN Data Transmission Function

The WriteAll() function sends control data for all motors via the CAN bus:

void WriteAll(){

//toggle = 1;

can1.write(a1_can);

wait(.00002);

can2.write(a2_can);

wait(.00002);

can1.write(h1_can);

wait(.00002);

can2.write(h2_can);

wait(.00002);

can1.write(k1_can);

wait(.00002);

can2.write(k2_can);

wait(.00002);

//toggle = 0;

}5.6 SPIne Firmware and PC Serial Communication

SPIne communicates with the PC through serial port for debugging and manual control:

void serial_isr(){

/// handle keyboard commands from the serial terminal ///

while(pc.readable()){

char c = pc.getc();

//led = !led;

switch(c){

case(27):

//loop.detach();

printf("\n\r exiting motor mode \n\r");

ExitMotorMode(&a1_can);

ExitMotorMode(&a2_can);

ExitMotorMode(&h1_can);

ExitMotorMode(&h2_can);

ExitMotorMode(&k1_can);

ExitMotorMode(&k2_can);

enabled = 0;

break;

case('m'):

printf("\n\r entering motor mode \n\r");

EnterMotorMode(&a1_can);

EnterMotorMode(&a2_can);

EnterMotorMode(&h1_can);

EnterMotorMode(&h2_can);

EnterMotorMode(&k1_can);

EnterMotorMode(&k2_can);

wait(.5);

enabled = 1;

//loop.attach(&sendCMD, .001);

break;

case('s'):

printf("\n\r standing \n\r");

counter2 = 0;

is_standing = 1;

//stand();

break;

case('z'):

printf("\n\r zeroing \n\r");

Zero(&a1_can);

Zero(&a2_can);

Zero(&h1_can);

Zero(&h2_can);

Zero(&k1_can);

Zero(&k2_can);

break;

}

}

WriteAll();

}5.6.1 Enter Motor Mode Function

The EnterMotorMode() function is used to put the motor into operating mode:

void EnterMotorMode(CANMessage * msg){

msg->data[0] = 0xFF;

msg->data[1] = 0xFF;

msg->data[2] = 0xFF;

msg->data[3] = 0xFF;

msg->data[4] = 0xFF;

msg->data[5] = 0xFF;

msg->data[6] = 0xFF;

msg->data[7] = 0xFC;

//WriteAll();

}5.7 SPIne Firmware Main Function Analysis

5.7.1 Main Program Flow

The main function is responsible for initializing the system and starting the main loop, continuously processing CAN messages and SPI communication:

int main() {

wait(1);

//led = 1;

pc.baud(921600);//Set baud rate

pc.attach(&serial_isr);//Communicate with PC

estop.mode(PullUp);//Emergency stop setup

//spi.format(16, 0);

//spi.frequency(1000000);

//spi.reply(0x0);

//cs.fall(&spi_isr);

//can1.frequency(1000000); // set bit rate to 1Mbps

//can1.attach(&rxISR1); // attach 'CAN receive-complete' interrupt handler

can1.filter(CAN_ID<<21, 0xFFE00004, CANStandard, 0); //CAN1 filter set up can filter

//can2.frequency(1000000); // set bit rate to 1Mbps

//can2.attach(&rxISR2); // attach 'CAN receive-complete' interrupt handler

can2.filter(CAN_ID<<21, 0xFFE00004, CANStandard, 0); //CAN1 filter set up can filter

//Allocate space

memset(&tx_buff, 0, TX_LEN * sizeof(uint16_t));

memset(&spi_data, 0, sizeof(spi_data_t));

memset(&spi_command,0,sizeof(spi_command_t));

//Set priority

NVIC_SetPriority(TIM5_IRQn, 1);

//NVIC_SetPriority(CAN1_RX0_IRQn, 3);

//NVIC_SetPriority(CAN2_RX0_IRQn, 3);

printf("\n\r SPIne\n\r");

//printf("%d\n\r", RX_ID << 18);

//Transmit data parameters

a1_can.len = 8; //transmit 8 bytes

a2_can.len = 8; //transmit 8 bytes

h1_can.len = 8;

h2_can.len = 8;

k1_can.len = 8;

k2_can.len = 8;

//Receive data parameters

rxMsg1.len = 6; //receive 6 bytes

rxMsg2.len = 6; //receive 6 bytes

//CAN ID setup

a1_can.id = 0x1;

a2_can.id = 0x1;

h1_can.id = 0x2;

h2_can.id = 0x2;

k1_can.id = 0x3;

k2_can.id = 0x3;

//Data buffer assignment

pack_cmd(&a1_can, l1_control.a);

pack_cmd(&a2_can, l2_control.a);

pack_cmd(&h1_can, l1_control.h);

pack_cmd(&h2_can, l2_control.h);

pack_cmd(&k1_can, l1_control.k);

pack_cmd(&k2_can, l2_control.k);

//Transmit

WriteAll();

// SPI doesn't work if enabled while the CS pin is pulled low

// Wait for CS to not be low, then enable SPI

if(!spi_enabled){ //Wait for SPI enable

while((spi_enabled==0) && (cs.read() ==0)){wait_us(10);}

init_spi();

spi_enabled = 1;

}

while(1) {//while main loop

counter++;

can2.read(rxMsg2);//Read data sent by motor controller

unpack_reply(rxMsg2, &l2_state);//Data parsing, assign to l2_state

can1.read(rxMsg1); // read message into Rx message storage

unpack_reply(rxMsg1, &l1_state);

wait_us(10);

}

} 5.7.2 CAN Data Parsing Function

The unpack_reply() function is used to parse CAN messages received from the motor controller and assign the data to the corresponding state structure:

/// CAN Reply Packet Structure ///

/// 16 bit position, between -4*pi and 4*pi

/// 12 bit velocity, between -30 and + 30 rad/s

/// 12 bit current, between -40 and 40;

/// CAN Packet is 5 8-bit words

/// Formatted as follows. For each quantity, bit 0 is LSB

/// 0: [position[15-8]]

/// 1: [position[7-0]]

/// 2: [velocity[11-4]]

/// 3: [velocity[3-0], current[11-8]]

/// 4: [current[7-0]]

void unpack_reply(CANMessage msg, leg_state * leg){

/// unpack ints from can buffer ///

uint16_t id = msg.data[0];

uint16_t p_int = (msg.data[1]<<8)|msg.data[2];

uint16_t v_int = (msg.data[3]<<4)|(msg.data[4]>>4);

uint16_t i_int = ((msg.data[4]&0xF)<<8)|msg.data[5];

/// convert uints to floats ///

float p = uint_to_float(p_int, P_MIN, P_MAX, 16);

float v = uint_to_float(v_int, V_MIN, V_MAX, 12);

float t = uint_to_float(i_int, -T_MAX, T_MAX, 12);

if(id==1){

leg->a.p = p;

leg->a.v = v;

leg->a.t = t;

}

else if(id==2){

leg->h.p = p;

leg->h.v = v;

leg->h.t = t;

}

else if(id==3){

leg->k.p = p;

leg->k.v = v;

leg->k.t = t;

}

}

6. Summary

This article systematically introduces the technical architecture and implementation details of the MIT Cheetah robot, covering the complete process from system architecture, simulation environment configuration, hardware platform selection to software environment setup. It focuses on analyzing the working principles and code implementation of the SPIne data communication conversion board, including SPI communication, CAN bus communication, and related data encapsulation and parsing mechanisms.

Through the detailed explanations in this article, developers can:

▪️ Understand the overall architecture and communication mechanisms of the MIT Cheetah system

▪️ Complete the full configuration process from simulation environment to real robot deployment

▪️ Master the core functions and implementation principles of the SPIne firmware

▪️ Perform secondary development and customization based on existing solutions

We hope this article can provide valuable reference for relevant technical developers and contribute to the further development and application of quadruped robot technology.

—

References:

Some content in this article references Chen Bu Chen’s Zhihu article, which provides an in-depth and excellent analysis of the technical details of the MIT Cheetah system. Special thanks are extended here.

Related Video:

Leave a Reply